A good economist can tell you that the changes in real GDP result from four factors: capital, labour, human capital, and technology. Yet, of these four factors, the only factor that does not get discounted is “technology.”

Output growth rate = (1/3 × capital stock growth rate) + (2/3 × labour hours growth rate)+ (2/3 × human capital growth rate) + technology growth rate.

Thus, technological progress contributes to economic growth significantly more than the other three factors, and history is a witness to this.

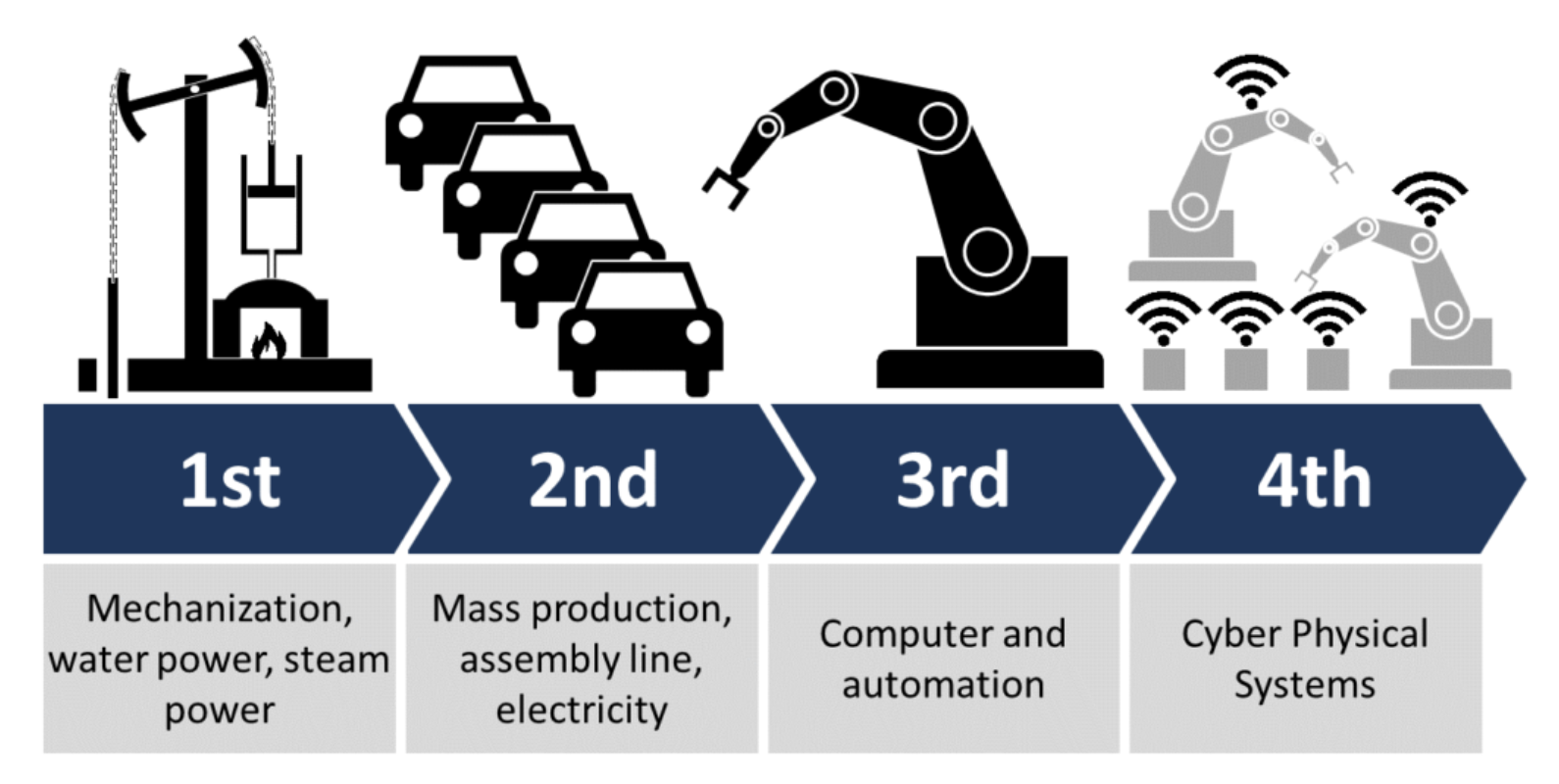

In the not-so-distant past, our industries underwent significant transformations during each industrial revolution, powered by the discovery and innovation of new technologies. From steam engines powering the first revolution to the rise of mass production due to the adoption of electricity in the second, and the digital age in the third, technology has brought about remarkable changes in our industry as well as our socioeconomic circumstances. Some of these changes had negative implications, such as urbanization, the creation of new social classes, economic inequality, colonization, and environmental damage. However, these revolutions also created the world as we know it today through changes such as globalization, labour rights and reforms, improved living standards, enhanced global transport and communication connectivity, and renewable energy.

Each industrial revolution created tectonic shifts in the structure and dynamics of human society and the global economy, some good, some bad. But it is important to note that none of these revolutions could be circumvented.

Today, we stand at the cusp of a new era, Industry 4.0, where technology and connectivity are once again reshaping the world of manufacturing and, indeed, every aspect of our lives. And just as history repeats itself, we will witness how new technologies reshape our society in new and exciting ways.

Yet, this time, it is different. The previous three industrial revolutions were driven primarily by the development or innovation of ONE technology. On the other hand, Industry 4.0 is instead the result of various technologies developing rapidly, the combined effect of which is revolutionizing our industry and society.

What is Industry 4.0?

The Fourth Industrial Revolution, commonly referred to as Industry 4.0, represents a fusion of a broad range of innovative technologies and practices that promise to transform industries like never before. The convergence of these technologies creates smart, connected systems that operate autonomously and make data-driven decisions, removing reliance on manual inputs and eliminating human errors. Let’s take a look at some of these technologies:

Industrial Internet of Things (IIoT):

IIoT is at the heart of Industry 4.0.

It involves connecting devices and sensors to the internet to collect and exchange data. In manufacturing, this enables real-time monitoring of equipment, predictive maintenance, and improved supply chain management.

With IIoT devices getting cheaper, more accurate, and more versatile, the amount of granularity in monitoring and control that manufacturers can achieve with these devices is unparalleled. Foxconn illustrated the value of this technology superbly, saving $1.6 Million per manufacturing facility annually by monitoring and improving energy consumption with IoT sensors.

Artificial Intelligence (AI)

After the release of ChatGPT, AI has become a part of everyday life. Industrial players are no exception.

AI allows machines to learn and make decisions. AI enhances efficiency and productivity across various industrial processes, from predictive maintenance algorithms to quality control. As AI and hardware converge, manufacturing will steadily move towards autonomous efficiency.

Big Data and Analytics

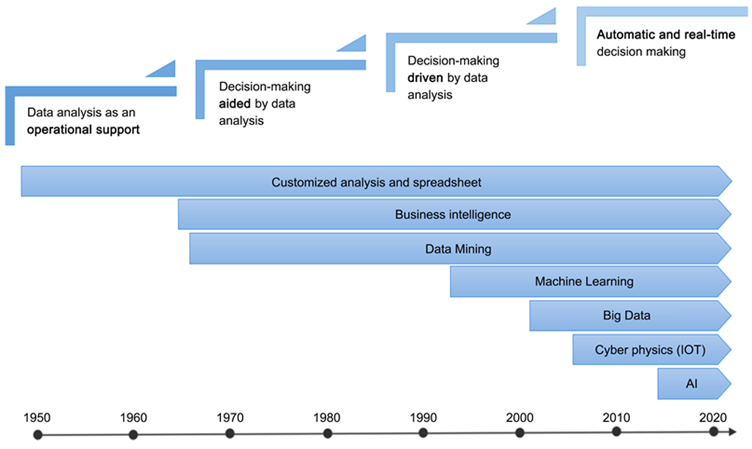

The connected IoT devices, sensors, machines, and industrial robots generate a massive amount of high-velocity data every day, with each sensor generating a new data point every second, creating the need for powerful analytics to extract valuable insights, optimize processes, and make informed decisions.

Data is at the core of decision-making.

Automation and Industrial Robotics

Automation is not new, but Industry 4.0 represents a significant evolution of this concept with advanced robotics and autonomous systems. Robots are getting more intelligent, more autonomous, more flexible, and cooperative as the intersection of robotics, advanced IoT sensors, AI, and connectivity takes industrial robotics to a new level of performance. Highly customizable, empowered with analytics, capable of decision-making, and increasingly user-friendly, robots today can perform complex tasks alongside humans, enhancing efficiency and safety.

The Impact of Industry 4.0

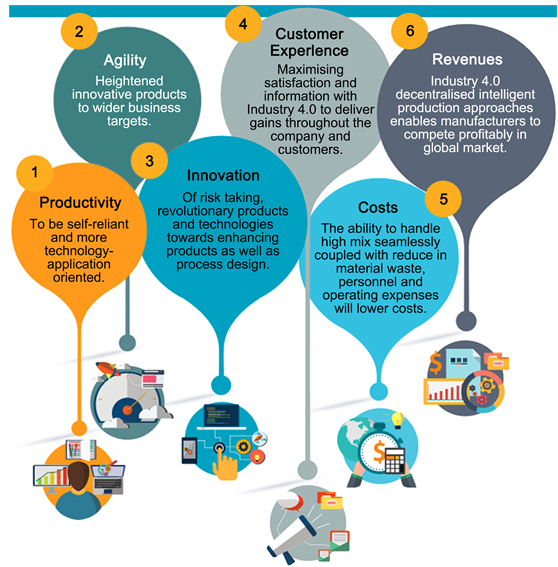

Industry 4.0 holds tremendous promise for our industries. Manufacturing processes are becoming smarter, more efficient, and more adaptable. Smart factories can customize products on demand, reducing waste and costs.

Yet, there are global concerns about the impact of automation and AI on employment and jobs. And this concern is echoed across various sectors (take the example of Hollywood writers protesting for protection against AI). This risk must be addressed, but it is challenging to quantify and qualify the exact effect of new technologies on employment. Many low-skill jobs are endangered, but studies show that replacing medium- or high-skilled jobs completely with technology is currently impossible. In the case of such jobs, technology is more likely to improve the quality of work rather than replace human input. Thus, increased adoption will definitely change employment as we currently know it. Yet, this can be seen as an opportunity for people to transition to more value-adding jobs that promise better work satisfaction.

Conclusion

Industry 4.0 is not a distant dream; it's our present reality. The fusion of technology and manufacturing is revolutionizing industries and changing the way we live and work. As we navigate this transformative era, one thing is clear: embracing Industry 4.0 is not just an option; it's a necessity for businesses and societies to thrive in the digital age.

And in this transformation, governments, leaders, and change-makers have a big role to play. Germany has been at the forefront of Industry 4.0 adaption since 2004, with the term “Industry 4.0” itself coming from BMBF (German Federal Ministry of Education and Research), and is joined in this drive for digitalization by Japan, South Korea, and China, to name a few. Apart from a push at the federal level, adoption of Industry 4.0 was also catapulted during Covid-19, as manufacturers became acutely aware of their dependence on labour and started seeing this dependence as a risk rather than an advantage.

The bottom line remains that, irrespective of the various challenges and barriers that stand in the way of digitalization for manufacturers, there no longer exists the luxury of choice. Even if you resist the new technology wave, your competitors are leveraging it to create new competitive advantages for themselves in a market increasingly characterised by competition and dominated by customer satisfaction. In such a scenario, your choices are simple:

You either adapt, or you perish.

Image Credit: “Christoph Roser at AllAboutLean.com“

Aishwarya Patki

Aishwarya Patki